Label printing and making machine NILPETER F 2400

Founded in 1919, Nilpeter Enterprise (Denmark) is a leading manufacturer of rotary printing machines for label production. It represents a wide range of narrow-web machines with a width of printed cloth from 250 mm to 420 mm, which use the different printing techniques, such as offset printing, flexoprint, silk screen printing, letterpress printing, gravure printing and hot foil stamping in various combinations, as well as digital printing presses.

The rapid development of the segment of packaging and labels and the increasing of market demand for high-quality printing products prompt the printing companies to look for the new solutions of improving the quality of products and reducing their cost price.

A narrow-web flexo printing machine Nilpeter F-2400 (Denmark) “races to rescue you”. It is one of the most popular and expensive models, especially in the field of label production. Many companies have bought this model in the days of Soviet Union.

The machine operates on the rotary principle (the use of cylinders with corresponding actuators) with the roll width 240 mm, printing width 220 mm and working width of cutting device – 230 mm (Co. Nilpeter manufactures machines with a larger width of the printed coil).

The number of printing units varies from 1 to 9 with drying of prints by hot air and UV radiation. The machine allows combining flexoprint with other printing methods. For example, it is possible to achieve a large thickness of the paint layer and the high saturation prints due to the appliance of rotary screen printing.

Printing machine Nilpeter FA-3300

This machine is unique due to its modular structure, which allows configuring it for work with a specific order and a specific type of raw material.

An open cantilever design provides an easy access to plate rollers, fountain rollers and raster rollers and maintains improved visual control of the web during the printing process.

FA-3300 allows combining flexoprinting, silk screen printing, gravure printing, and a variety of finishing processes in one machine.

The number of printing units varies from 1 to 12. Nilpeter FA-3300 is equipped with a new computer-assisted command system with touch screen which displays technical data and service information. This system can help to make on-line connection with Co. Nilpeter to control the equipment performance.

This machine has a low noise level. The waste materials of expendables are minimized. The environmental issue is solved. That is why Nilpeter FA-3300 is the number one machine for your business. Its production has a low cost-price and high-quality printing. So the flexographic printing machine FA-3300 is ideal equipment for printing business not only in its infancy, but also during its prosperity.

Inkjet printer Linx

Nowadays an industrial marking of goods is necessary in the fields of producing units, packaging and storage of goods, in retail business and wholesale trade etc. Commercial marking is a label, a tag, which are used in the manufacture, storage, transportation of goods for industrial use or packaging. These products are exposed to great loads, so there are tough requirements to their labeling. First of all, labels and tags should be firm and tight. If labeling for industrial goods is perfectly executed it can also become an additional advantage of a product. According to our law, products should contain all necessary information about the manufacturer, shelf life, etc. Today there is a huge number of different marking equipment, modern technologies and application methods of industrial marking, so it is quite difficult to choose among them. And there is no unified solution. Manufacturers often use the special marking machine: this equipment helps to make industrial labeling in industrial-scale volumes very quickly. The inkjet marker (inkjet printer) has multi-zone applications. It is a marking machine and a dater machine, so it can combine several functions. Plus this device puts all necessary information on the package quickly and very clearly.

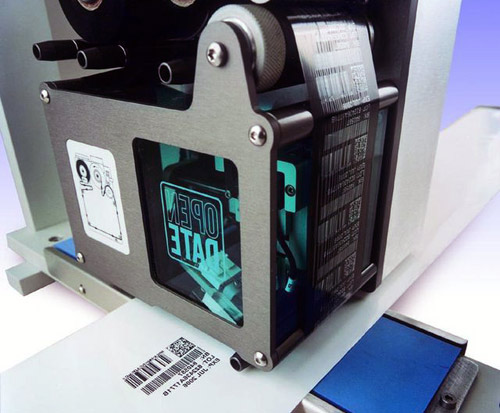

Thermal transfer printer TSI

Thermal transfer printers are usually used for barcodes printing or for printing other letter-digital information. In contrast to the other printing methods, printing on the thermal transfer printer is more tight and durable. It is important in printing barcodes, which are usually used quite extended period of time. Thermal transfer printing is relevant in cases when you need to print labels, tags and signs on the containers with chemical agents, substances and acids, when common printed labels are not appropriate. In addition, not all plastic material can stand the pressure of the laser scribing coder. So thermal transfer printer comes to assistance!